The history of OEM vs. PMA brake parts manufacturers is a long war of words.

What is PMA?

“PMA” is an acronym for “Parts Manufacturer Approval.” It is both a design and production approval issued by the FAA. Basically, the FAA permits the manufacture of replacement parts for aircraft if the part has been tested and meets FAA standards for airworthiness and the part is manufactured in accordance with FAA approved procedures.

The replacement parts market started back in the 1950s with specialty manufacturers catering to enthusiast pilots in need of parts for obsolete WWII planes. Gradually, small manufacturers sprung up to offer replacement parts for contemporary aircraft. Over the years, regulations were added that more closely aligned the certification rules for the PMA parts industry with those of the OEM and Production Certificate holders.

In 2011, FAA Part 21 regulations were revised. They now more clearly identify PMA as a special type of production certificate and eliminate many distinctions between OEM and PMA manufacturing. PMA regulations now also reference FAA regulation 21.137, which is the regulation defining the elements of a quality system for all production approval holders.

PMA Approval Process

The PMA process, regulated by the FAA, is a meticulous procedure ensuring the airworthiness of replacement aircraft parts. Companies seeking PMA approval undergo a rigorous application, risk assessment, and engineering testing phase. Verification of installation usability, adherence to FAA regulations, and the establishment of production systems are crucial steps. Manufacturing Inspection District Offices (MIDO) monitor compliance, certifying that each part aligns with FAA-approved designs. The PMA process demands strict adherence to industry standards to guarantee the safety and reliability of replacement components.

PMA Part Range and Design Flexibility

Our range of PMA parts encompasses critical components to non-critical parts, showcasing design flexibility. This flexibility allows us to enhance OEM designs or address known issues, ensuring our parts meet or exceed industry standards. The ability to implement minor changes or improvements enables us to deliver PMA parts tailored to diverse needs within the aviation industry.

PMA Quality Control Process

Ensuring the highest standards for Parts Manufacturer Approval (PMA) parts is a primary focus at our facilities. Our design approval stage involves demonstrating compliance with FAA standards for replacement or modification parts. The subsequent production approval stage requires thorough checks to meet specifications before any product leaves our facility. We work closely with Manufacturing Inspection District Offices to ensure adherence to production and quality systems. Throughout the manufacturing process, a series of quality gates act as checkpoints, ensuring that each part aligns with material and customer specifications for aerospace and industrial applications.

Breaking the OEM Stranglehold

For years, OEMs not only enjoyed a virtual monopoly on replacement parts, they also had carte blanche to raise their already high prices every year. Great for OEMs, terrible for flying enthusiasts. Compounding the misery, OEM parts were often backordered for weeks or months.

The surge in commercially available PMA Approved replacement parts as we know them today didn’t come until the 1990s. As you can imagine, OEMs were in a panic, as they've never seen competition before. A brake they used to charge $3,600 for was hastily marked down to a more competitive $800. In an effort to salvage their lucrative replacement parts business, they embarked on an unfounded smear campaign against PMA parts.

Over the years, OEMs have tried just about everything to make you think PMA parts are inferior to OEM parts.

For instance, one OEM ran an ad showing a pathetic Elvis impersonator with the headline “Let’s face it, lookalikes never perform quite like the original.”

The ad earned them a public slap down from the FAA. In a Special Airworthiness Information Bulletin, the FAA stated that when they approve a PMA part they fully expect:

“the industry will treat that approval with the respect that a decision of the FAA deserves, and that furthermore, such parts are entitled to the full recognition of the FAA’s approval, and it is not up to the engine manufacturer to say that installation of a PMA part is wrong or invalid.” - view more information on the FAA statement

In 2011, GoodRich-Messier, Inc. tried to pull a fast one by requiring anyone accessing their technical publications to agree to not use any PMA parts- and to install "only Goodrich-Messier, Inc.-authorized parts...during maintenance and overhaul." They claimed there were concerns about parts not authorized by Goodrich-Messier, which "may compromise the performance and reliability of the wheel(s) and braking system." Nice try, but it didn't fly.

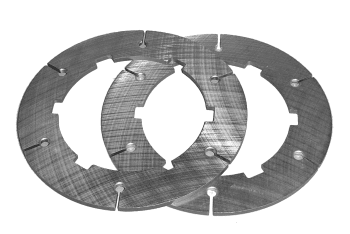

OEM alternative brake components must be extensively inspected and flight tested to achieve PMA approval.

OEM Quality and Standardization

Original Equipment Manufacturer (OEM) parts, stemming from the original aircraft manufacturer, boast a consistent design across fleets. Renowned for their proven performance and adherence to standardized designs, OEM parts have a track record of reliability in the original equipment. These parts strictly comply with industry and regulatory standards, ensuring airworthiness. The material and design quality gates established for OEM parts underscore their reliability and consistency in meeting precise specifications.

OEM Brake Parts vs. PMA Brake Parts

While OEM brake parts get their approval authority simply by virtue of being on the aircraft when it was originally certified as a whole, we earn our approval by actually proving the performance of the brake parts themselves.

We document hundreds of design landings using a full-scale wheel on a state-of-the-art brake dynamometer before we even get approval to conduct a strict FAA-mandated flight test. A complete flight test includes landings at various weights, water contaminated landing conditions and max-weight rejected take offs (RTO). We have to prove compliance with applicable airworthiness standards and substantiate that the PMA-candidate part is equal to or better than the original OEM part.

Since we take safety and engineering seriously, we make sure our parts don't just meet the FAA’s performance standards and airworthiness requirements, we typically exceed them.

Price Difference between PMA and OEM Parts

A significant factor contributing to mechanic skepticism revolves around the notable price difference between PMA and OEM parts. PMA parts are generally more affordable, creating a perception among mechanics that the safety and quality reside in the higher-priced OEM products. The price differential becomes a focal point for skepticism, as mechanics may question why PMA parts are more economical and whether this compromises their overall performance.

It is crucial to address this concern by highlighting that price disparities between PMA and OEM parts are influenced by various factors unrelated to safety or quality. Explaining these factors can help mechanics understand that cost-effectiveness does not equate to compromised reliability.

Historical Context

The aviation industry has faced challenges related to unapproved parts scandals in the past, contributing to the lingering concerns among mechanics. Unapproved parts, which were frequently available at significantly lower costs than approved parts, posed serious safety and quality risks. Although PMA parts are approved and have undergone extensive testing, the historical context of unapproved parts scandals has left a lasting impact on the industry's perception.

It is important to distinguish PMA parts from the unapproved parts of the past, emphasizing that the approval process and oversight by the Federal Aviation Administration (FAA) ensure the safety and quality of PMA parts. This contextual understanding can help alleviate concerns rooted in historical incidents.

Mechanic Skepticism and Perception

Many mechanics, particularly in general aviation and corporate settings, harbor skepticism when it comes to Parts Manufacturer Approval (PMA) parts. Despite undergoing the same rigorous approval process as Original Equipment Manufacturer (OEM) parts, a lingering doubt persists within the industry. Mechanics often express concerns about the equivalency of PMA parts, questioning whether they can truly match the quality and safety standards set by their OEM counterparts.

This skepticism primarily stems from the perception that lower prices associated with PMA parts might compromise their reliability or durability. The prevailing belief among some mechanics is that the cost discrepancy between PMA and OEM parts implies a difference in quality, with the assumption that higher-priced OEM parts inherently translate to superior safety standards.

RAPCO Fleet Support is Your Best Source for PMA Parts

Since 1987, RAPCO Fleet Support has been providing high-quality FAA/PMA approved brakes and brake parts to airlines and parts distributors all over the world. Our parts help reduce costs with absolutely no compromise on safety, performance or durability. From our central location in southeast Wisconsin, we ship promptly to customers all over the country. Learn more about Rapco Fleet Support and why our PMA parts are among the best in the industry.

PMA Quality Conclusively Proven in FAA Study

Back in 2008, in response to persistent lobbying by fear mongering OEMs who claimed PMA parts were still a threat to aviation safety, the FAA undertook an extensive Repair, Alteration, and Fabrication (RAF) study.

Besides reviewing all the regulations, policies, and practices pertaining to the PMA approval process for replacement parts, the FAA study also took a critical look at the real world performance of PMA replacement parts to get a picture of how they might be failing and how often.

Conclusion: There was no evidence of failures or unsafe conditions caused by PMA parts and, despite a substantial increase in their use, there was no proportional increase in service difficulties or airworthiness directives on PMA parts.

What About Parts for Aircraft Serviced in Foreign Countries?

The FAA realized years ago that aircraft production is often a global endeavor. Anticipating issues with differing standards around the world, they formulated a plan for global regulatory oversight to ensure the airworthiness of parts from any country.

Find links to distributor websites on our distributors page.

We carry PMA brake parts for aircraft including:

To guarantee consistent quality, the FAA developed Bilateral Aviation Safety Agreements (BASAs). These agreements mirror the rigorous certification and approval process required for FAA Parts Manufacturing Approval in the United States. So, no matter where in the world you go, an FAA-PMA part provides consistent quality.